| with edit by Norm Hall

Printer Friendly (PDF)

The Monday Morning Minute articles for the last few weeks focused on condensing boiler efficiency in response to modulation and return water temperatures during reset. When thinking about new systems there is a real advantage to using greater temperature differences in the design.

Using a 20°F ΔT as a design standard could be a thing of the past. As we design systems today we try to maximize the overall efficiencies and total cost of ownership. One way to accomplish that is by using a ΔT larger than 20 degrees. This type of thinking parallels ASHRAE 90.1 and LEED and will help to keep money in the owners pocket. Let’s take a look at the math.

Q=500 X GPM X ΔT X Sp.Gr X Sp. Ht.

Where Q is the heat generated in BTUH; GPM is the Gallon per minute flow rate; Delta T, ΔT, is the design difference between the supply and return water temperature. At normal water temperatures for hydronic systems the specific heat and specific gravity are about 1.0. If we design the system to maintain BTUH while raising the ΔT the GPM will be lower.

For example If you had a system with a 30 degree ΔT using a 1:1 reset ratio with a 0°F outdoor design temperature and a 180°F design water supply temperature, the boiler could be condensing at a low outdoor temperature of 15 to 20°F. Imagine if we used a 40°F ΔT for the same system, we could be condensing at an outdoor temperature of 5 to 10°F. Higher efficiency more of the time!

Along with the increased efficiency of the boilers the overall pumping horsepower is reduced due to the lower flow from the higher ΔT. This lower flow will reduce the pipe sizing, control valve sizing, insulation, and compression/expansion tank size due to lower system volume.

Using lower flow rates and lower average temperatures will require increases in the square feet of terminal units. Most terminal units, properly selected, can handle the change with 10 to 20% more surface. We find the reduced cost of piping, valves, and pumps outweighs the cost increase in terminal units and the end user is left with a system designed for higher efficiency and lower operating costs.

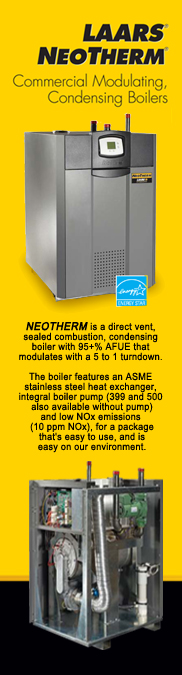

Ask your R. L. Deppmann sales engineer to review these changes on your next project while specifying High Efficiency Condensing Boilers by Laars, Aerco, and Bryan. |