| Printer Friendly (PDF)

Pump curves are based on water, but I am pumping a glycol solution. How will this affect the selection? This week we define the first of three glycol corrections. There are three glycol corrections when designing a hydronic or process cooling system; heat transfer correction, pressure drop correction, & pump curve correction. The first correction we’ll look at is heat transfer correction. When choosing chillers, boilers, heat exchangers, and terminal units, it is important to select them using the correct system fluid. If a heat exchanger system requires a 30% water-propylene glycol mix, use that in the calculation. Likewise, if your cooling system design requires a 50% Ethylene glycol-water fluid, then the chiller and coil designs should be based on that fluid. This way the heat transfer correction is built into the selection.

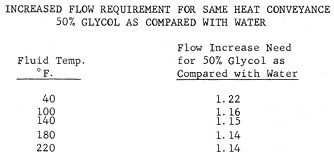

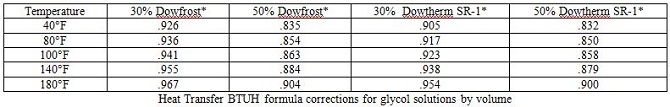

What do we use if the system is existing and we are changing from water to glycol? How do we “de-rate” the system if the fluid is changing to glycol from water? This is when we use a “heat transfer” correction. When we change fluids, there are two choices: either we de-rate the BTUH of the system or we have to increase the flow rate intending to increase the U value. This assumes the velocity may be increased without reaching the maximum velocity limitation of the device. Tables, such as the Bell and Gossett one listed above, provide rules of thumb to avoid de-rating the BTUH capacity of a system by increasing the velocity. If you need to de-rate a system, use the BTUH formula: BTUH = GPM x ∆T x 500 x SPg x SPht. The specific gravity multiplied by specific heat becomes the correction. Here is a table created from Dow’s catalog of Dowfrost* and Dowtherm* heat transfer fluids.

Example: Given an existing system with 1,000,000 BTUH output using water as the medium, what is the BTUH output expected if we fill the system with 30% SR-1 at 140°F? Solution: 1,000,000 X .938 = 938,000 BTUH output. Next week we look at glycol pressure drop corrections. * Trademark of The Dow Chemical Company |

||||

|

Disclaimer: R. L. Deppmann and it’s affiliates can not be held liable for issues caused by use of the information on this page. While the information comes from many years of experience and can be a valuable tool, it may not take into account special circumstances in your system and we therefore can not take responsibility for actions that result from this information. Please feel free to contact us if you do have any questions.

Archives – Click here for Past Articles