The purpose of the domestic water recirculation system is to delivery hot water near a fixture during times when there is no draw. If someone is using hot water in the next room or apartment or process; the hot water is near enough to your fixture so the hot water is delivered in seconds, not minutes.

Plumbing Topic: Domestic Water Recirculation Systems Part 2

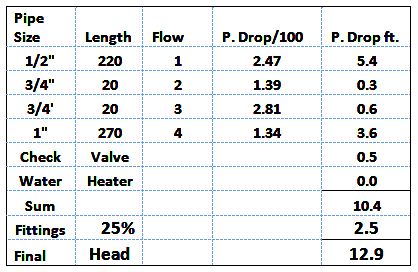

Let’s assume the domestic hot water supply is a total length of 1000 ft. That is the entire pipe on all of the floors. Let’s also assume an average of 15 BTU/hr/ft of loss through the supply pipe insulation. Now let’s assume the recirc piping is 300 ft total at an average of 10 BTU/hr/ft of loss. What flow rate is required for a 10 degree ΔT? What flow rate is required for a 5 ΔT?

Domestic Water Recirculation Systems Part 1: Flow Rate

The R. L. Deppmann Monday Morning Minutes series will focus on the plumbing portion of the new construction and building facility business for the next few months. The topics will be domestic water recirculating systems, pressure booster systems, volume and instantaneous water heaters, and mixing valves. I’ve had 6 job site visits in the last 2 months to help engineers, service contractors, and facility managers solve problems with domestic water recirculating systems. It seems this is a good place to start.

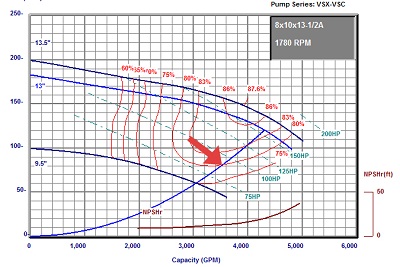

Solving Oversized Pumping Problems

The last two weeks we used the Pump Affinity Laws and the Xylem Bell and Gossett System Syzer® to either trim the impeller or reduce …

The Bell and Gossett System Syzer and Pump Affinity Laws – to resolve a field problem (Part 2)

Last week we used the Pump Affinity Laws to determine what size the impeller would be trimmed to in an oversized pump. Reducing the speed …

The Bell and Gossett System Syzer and Pump Affinity Laws – to resolve a field problem

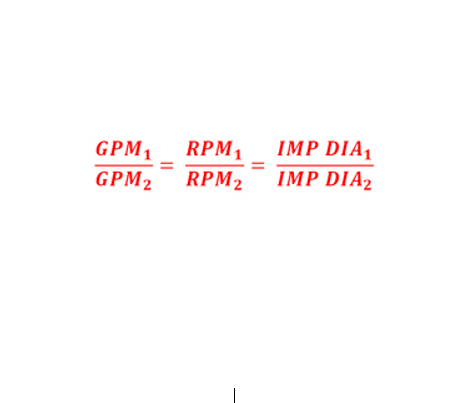

The Pump Affinity Laws are used to determine the system curve. If we know the point of operation on a pump curve, we can determine …

The Bell and Gossett System Syzer and Pump Affinity Laws

Hydronic heating system flow rates and pressure drops are related through a series of AFFINITY LAWS. Let’s examine the laws and how to use them …

Match the Steam Trap to the Control Valve Type (Part 2): Types of Traps

Which style of steam trap should I use when I have a modulating control valve? What happens if I “lift” out of a steam trap? …

Match the Steam Trap to the Control Valve Type (Part 1)

Steam heating systems are a dying breed in commercial and institutional heating systems. Engineers and contractors understand a great deal about hydronic heating systems. Sometimes, …

How to Limit the Speed of the Pump Using a Danfoss Variable Frequency Drive

In this Monday Morning Minute, we demonstrate how to limit the speed of the pump using the Danfoss Variable Frequency Drive (VFD).