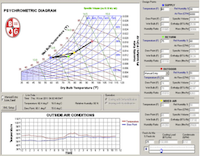

Xylem Bell and Gossett recently announced the new System Syzer programs for your computer. You may download these through links on our website at the www.deppmann.com/resources/ page. This new tool has a powerful lineup of useful features. Let’s look at a couple of them. Continued from Part II

Using the New Bell and Gossett System Syzer Programs PART 2

Xylem Bell and Gossett recently announced the new System Syzer programs for your computer. You may download these through links on our website at the www.deppmann.com/resources/ page. This new tool has a powerful lineup of useful features. Let’s look at a couple of them. Continued from Part I

Using the New Bell and Gossett System Syzer Programs

Xylem Bell and Gossett recently announced the new System Syzer programs for your computer. You may download these through links on our website at the www.deppmann.com/resources/ page. This new tool has a powerful lineup of useful features. Let’s look at a couple of them.

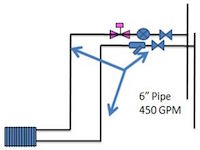

Air Separator Location in Hydronic Systems

R. L. Deppmann is offering another series of seminars, this fall, which are centered on “Energy Savings and ASHRAE 90.1 and 189.1 standards”. During a couple of the first 7 seminars, the question of the air separation location sparked a short discussion. Let’s review the response in this Monday Morning Minute.

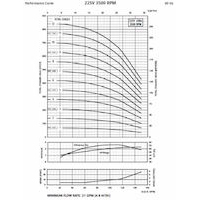

Minimum Flow in Variable Speed Pumps for HVAC and Building Plumbing Systems

Every week a question comes in to R. L. Deppmann about the minimum flow rate through pumps. In hydronic heating and cooling systems, it is …

Triple Duty® valves on your variable speed hydronic pumps

Bell and Gossett triple duty valves have, for decades, provided a cost effective way to assure there is a non slam check, balance, and shutoff valve on the discharge of your hydronic pump installation. These valves are used to throttle excess head and, therefore, should not be oversized. B&G offers these installation friendly valves in traditional full port model (3DS-S) and in a reduced port version (3DS-B)

Update and Upgrade Your Hot water Boiler Controls to Save $$

The RBT-3000 is a combination safety and energy saving device for installation on hot water heating boilers. The low water cut-off turns off the burner when an unsafe water loss occurs in the system. The energy saving feature reduces fuel consumption, wear on boiler parts and burner emissions. The control actively manages the burner cycling along with the operating control to match boiler output to the required load.

A Cost Effective Domestic Water Recirculating for smaller systems

In today’s economy there are many small office, retail, and tenant fit-out work jobs than large expansive projects. These smaller projects come with tighter budgets. Here is a tool you may not be aware exists. Bell and Gossett ECO-CIRC under sink recirculating pump available for tank type water heater as well as tank-less systems. High efficiency and lead free brass construction.

“What is Pulse Technology?” and “Why We Use it to Affect Water Quality.” – Part 3

The objective of water treatment is to:

*INHIBIT CORROSION, prevent mineral scale & control bacteria, biofilm & legionella. In this Monday Morning Minute, we will discuss the technology and the effect that pulse technology via the Griswold Wave product provides specific to corrosion inhibition.

“What is Pulse Technology?” and “Why We Use it to Affect Water Quality.” – Part 2

The objective of water treatment is to: *CONTROL BACTERIA, BIOFILM AND LEGIONELLA, Inhibit Corrosion, & Prevent Mineral Scale. In this Monday morning minute, we will discuss the technology and the effect that pulse technology via the Griswold Wave product provides specific to microbial control.