The water quality in hydronic systems directly affects the performance and life expectancy of the components in the systems. Total dissolved solids (TDS) and pH levels are two factors that have a big impact on hydronic systems.

Mechanical pump seals can be particularly vulnerable to “dirty water.” For a standard mechanical seal, the recommended maximum conductivity (measurement of TDSs) is 400 ppm and the recommended pH level is between 7.0-9.0. Operating outside of these levels can lower the heat transfer capabilities, cause corrosion, and break down the O-rings and seals in the system. In addition, poor water quality can also void the manufacturer’s warranty on your equipment.

Water Quality Tests and Seal Selection Info

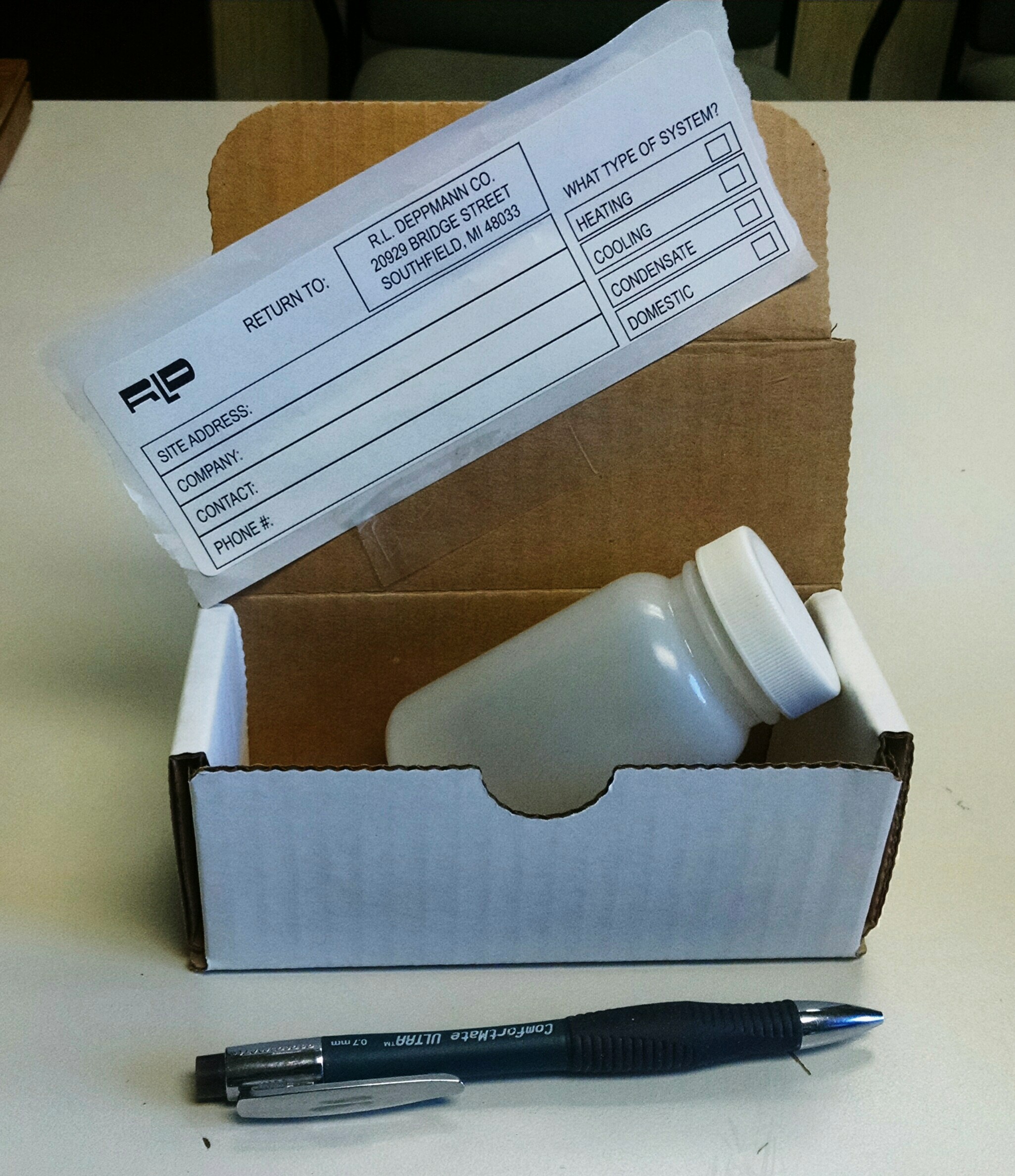

R.L. Deppmann offers free basic testing for TDS and pH in order to help customers select the right seal for their application. We can also have water samples tested for glycol concentration.

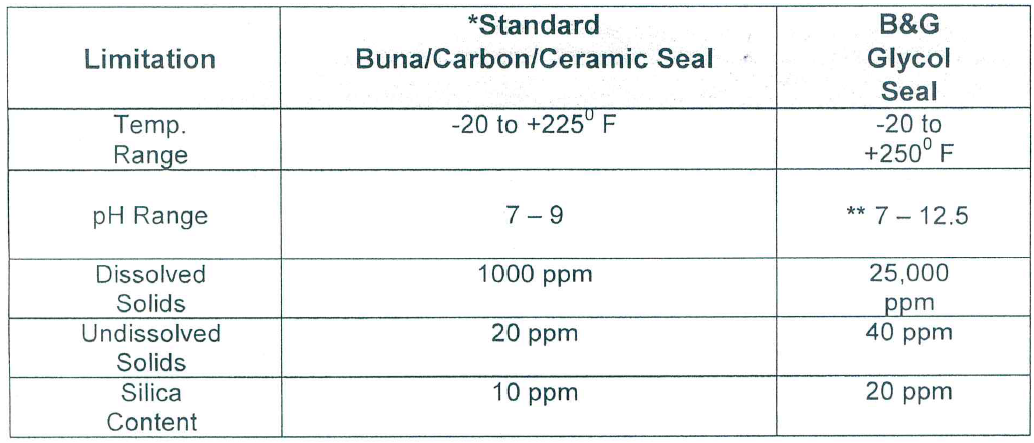

In the event that your system tests outside of the recommended ranges, in many cases a “glycol seal” (or EPR/SiC/Sic) can help protect your Bell & Gossett pump. The primary mating seals of this seal are made of silicon carbide and have operating limits that approach 20,000 ppm and a pH range between 7.0-12.0. Below is a comparison of various types of seals and their limitations.