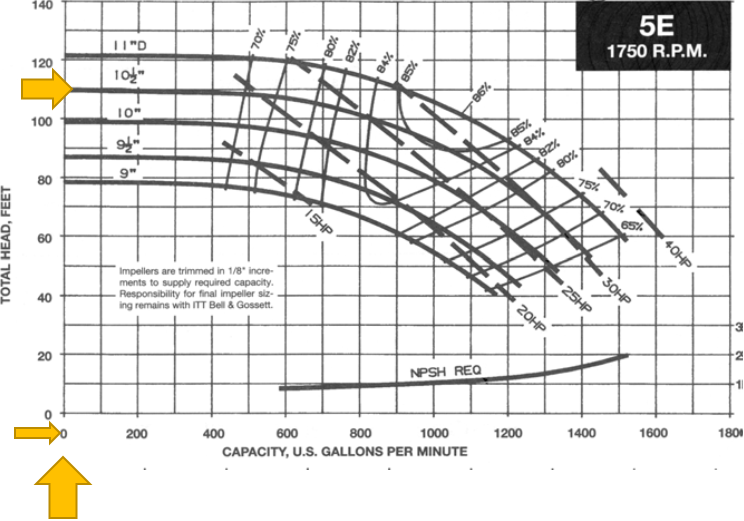

Here is a quick way to determine impeller size from the No Flow point on the pump curve.

Tools needed:

1) Pump curve. Select the proper curve from the manufacturer’s casting numbers.

2) Pressure gauge. Head (ft/hd) = Pressure (psi) X 2.31

How to Determine Impeller Size

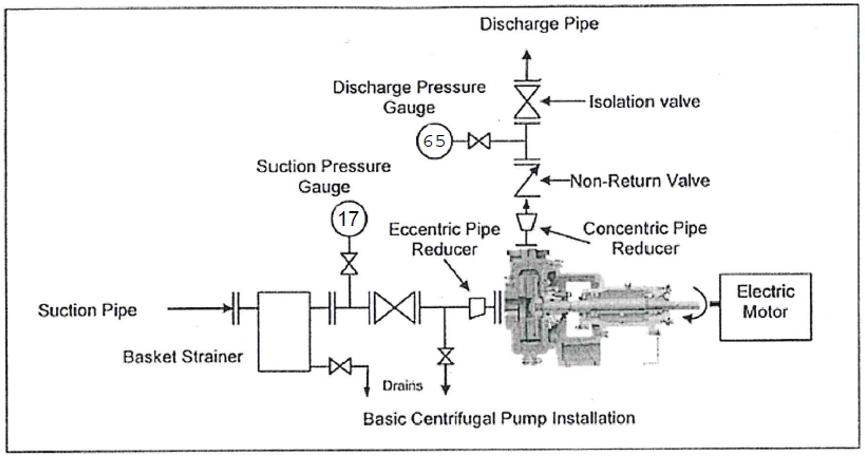

1) While the pump is operating, close the discharge valve and record the suction and discharge pressures. Reopen the discharge valve and reset to the position before closing.

Discharge pressure – Suction pressure = Differential Pressure

Example: 65 psi – 17psi = 48 psi differential pressure

48 differential pressure x 2.31 = 110 ft/hd

2) The total dynamic head is generated from dead heading the pump. We can determine the impeller size from the no-flow point on the pump curve.

CAUTION: Dead heading occurs when the discharge of the pump is closed off by either a closed valve or a blockage. This condition MUST be avoided. Pumps have exploded from the super-heated pressure caused by running the pump with the discharge valve accidentally closed.

For more information about determining impeller size, contact us.