Over the last few weeks the Monday Morning Minutes (MMM) posts have reviewed the use of tankless water heaters vs. traditional storage type water heater systems. With all the news these days, it’s difficult to leave the subject of plumbing hot water systems without some comment about Legionella.

Let’s start with a disclaimer. I’m an engineer and not an expert on Legionella causes and prevention. This article is not intended to be a design guide but does offer a few solutions to concerns we’re hearing from customers. Those concerns are the minimum water temperature in the system and the possible issues caused by stagnant water.

Temperature & Legionella in Service Water Heater Systems

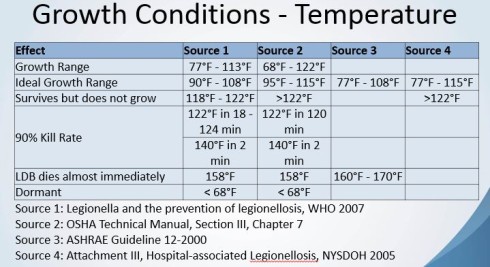

The following two charts were provided by AERCO and are part of their presentation on Legionella in plumbing systems. Contact your local AERCO representative if you’re thinking of using this subject for a local ASHRAE or ASPE meeting.

The first chart shows the effect of temperature on legionella pneumophila bacteria. This bacteria is present in rivers, lakes, streams, and other sources. Given all the prevention methods in municipalities, this bacteria may still find its way into the plumbing system. As you can see from the chart, we can almost instantly kill the bacteria if we heat the water to 160°F. We also see the bacteria’s death if we keep the water temperature above 140°F for several minutes or 130°F for several hours.

Engineers are often concerned about storing water where there may be stratification. Stratification results in reduced temperature in the storage tank. The tankless solution eliminates the tank but does not eliminate the temperature issue unless you supply very hot water.

Temperature & Safety in Service Water Heater Systems

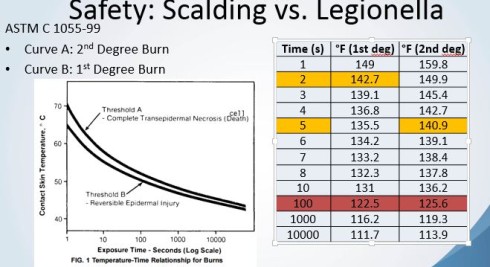

The second chart shows the danger of scalding based on supply water temperature at the fixture. It is clear that although Legionella can be killed at 160°F, there must be protection against the high temperature ever reaching the occupants. Somehow, the engineer must design a hot water system with both charts in mind.

Designing Plumbing Systems

If you’re concerned about keeping water temperature above 122°F and reducing stagnation in your system, here are a few thoughts to consider.

- Let’s assume we eliminated the storage tank and used tankless water heaters.

- Although many designs cycle the domestic water recirculating pump on and off to save energy, we may want to keep the pump running.

- Instead of designing with a return water of 115-120°F, we may want to design with an expected return water temperature of around 125°F.

- Using the 125°F return, calculate the BTU loss for the system at the worst case. This involves the pipe size, conductivity and thickness of the insulation, as well as the length of each pipe size. Determine the supply water temperature required. If you’re using a tankless system and using ASSE thermostatic protection point of use valves at all fixtures, set this as the supply temperature.

- Determine the flow rate required for each balance valve to maintain your design ΔT on each loop. Keep the minimum flow rate high enough to avoid issues with plugging due to water quality and small orifices in the balance valves.

These are some thoughts for consideration in your design. We’ll expand on this in our fall 2016 seminars on domestic water pumping systems.

References for More Information

- U.S. Dept. of Labor: Legionnaires Disease

- Wikipedia: Legionella

- New York Dept. of Health: Information on Legionnaires Disease

- ASHRAE Guideline 12-2000

- ASTM C 1055-99