The pump suction piping and specialties are somewhat simple but can be a cause of headaches if a few simple rules are forgotten. This week the R. L. Deppmann Monday Morning Minutes looks at the pump suction piping and trim. The basic piping on a pump suction includes the shutoff valve, the strainer or suction diffuser, the flexible connector (if specified), and the reducers, elbows, and pipe. Today we will look at the strainer.

The pump suction piping and specialties are somewhat simple but can be a cause of headaches if a few simple rules are forgotten. This week the R. L. Deppmann Monday Morning Minutes looks at the pump suction piping and trim. The basic piping on a pump suction includes the shutoff valve, the strainer or suction diffuser, the flexible connector (if specified), and the reducers, elbows, and pipe. Today we will look at the strainer.

Before I begin, I will answer a couple of questions I received about last week’s blog about check valves on pumps.

Question 1: What about using Metraflex silent check valves in plumbing applications? The folks at Metraflex report that their silent check valves follow NSF-372 (lead-free) standards and follow the Manufacturers Standardization Society (MSS) of the Valve and Fittings Industry MSS-SP-125-2010.

Question 2: What about check valves that leak because of metal to metal seats? This is by design. There is an acceptable amount of leakage in MSS-SP-125-2010. If you want bubble-tight (zero leakage), there are rubber seats available in some check valves to provide zero leakage. But in a closed hydronic system, we have shut off valves for service.

In addition, where is a closed system the water will leak to? By definition, the system is filled with water except in the expansion tank, so there is no place for the water to leak. I would not waste any money on “Leak Proof.” I’ll cover this in the specification at the end of this series.

Now back to pump suction piping. Just a quick note, we should always defer to the pump manufacturer’s recommendations when it comes to installation, operation, and maintenance. The pumps we recommend in HVAC and most plumbing applications are manufactured by Bell & Gossett, a Xylem Company.

The Hydraulic Institute

Most of the pump companies you see in the hydronic and plumbing world are members of an organization called the Hydraulic Institute, also referred to as simply, HI. The majority of HI members are pump companies and their suppliers. Many, but not all, of the pump companies we see in specifications are members of this organization. HI publishes standards for all sorts of pumps. Not just the pumps we use in the relatively simple duty of building heating, cooling, and plumbing, but industrial pumps in, for example, oil refineries and chemical process. These standards include, for example, nomenclature standards, testing standards, and installation standards. They set down some ground rules so, for example, your pump curves look similar and the curves are verified to be correct with a similar set of tests. The Bell & Gossett brand’s parent company, Xylem Inc., is a very active member. You may be surprised to find pump companies in your specification who are not members!

You can think of the Hydraulic Institute standards just as we think of the American Society of Heating, Refrigeration, and Air Conditioning Engineers (ASHRAE). ASHRAE is a group of member engineers and associated people who volunteer to join standards committees. These committees are charged to determine standards from fundamental terms used to system design ideas to the concepts used in design to the testing or commissioning of the systems. HI does the same thing. The only difference, as I understand it, is that the members are companies and not individuals.

You will hear and see the Hydraulic Institute standards or HI often mentioned in the manufacturer’s literature and guide specifications. I will also refer to HI when writing about the installation of pumps.

Strainers and the HVAC Centrifugal Pump Suction

The strainer might be a traditional old style wye strainer or even a higher efficient strainer like the Metraflex LPD. It may also be a basket style strainer. In addition to body style, they also have different screen sizes. Strainers may come with different size holes or mesh or perf. You can see an example of this in an article I published on steam strainers.

The thing about a strainer is that it will clog up. When it clogs up, the pressure at the pump suction will drop. If the strainer plugs up too much, the pressure in the pump suction may drop down so low that the water turns to vapor. This whole story is the story of net positive suction head (NPSH) and the NPSHR “required” by the pump.

Strainers on pump suctions protect the pump from larger items that could damage the impeller. In general, there is no need to “strain” all of the particulates out of the water to protect the pump. The smaller the holes in the strainer, the faster they plug. Most pump strainers have 1/8” holes in them. This is plenty big enough to catch the things that may damage a pump. This is what I recommend you use. It is also standard on most strainers used for water service in hydronic applications.

If you need a finer mesh strainer for a device downstream, install a strainer at the device. For example, there are many chillers available that use brazed plate heat exchangers similar to the B&G BPX. The chiller may require a 20 mesh strainer to protect the small openings in the chiller heat exchanger. Well, a 20 mesh screen has a hole that is 0.033 inches. This is quite a sieve compared with the 0.125-inch pump strainer. If that fine mesh strainer is put on the pump, there could be problems.

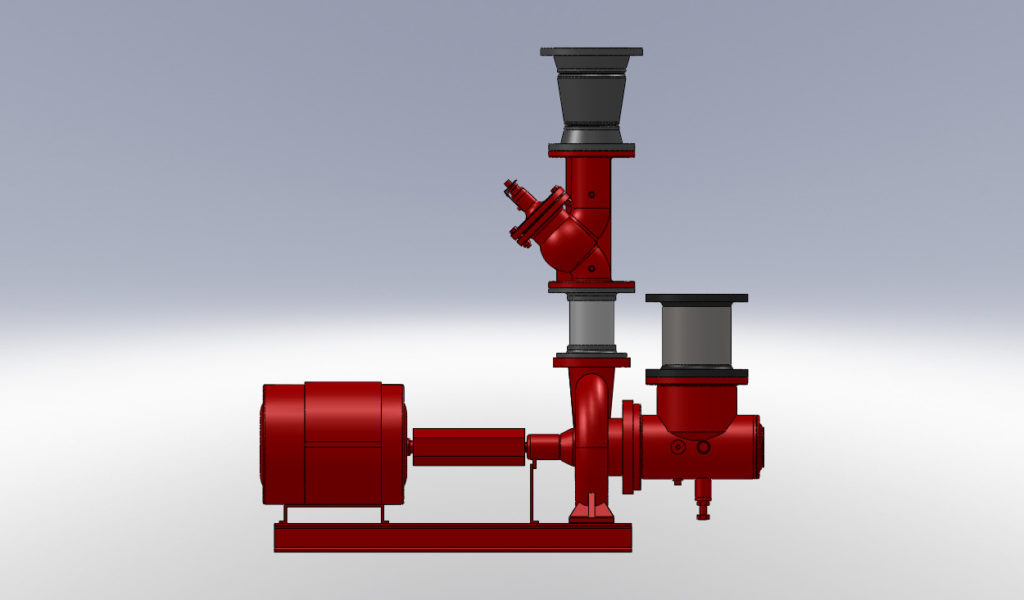

Bell & Gossett Suction Diffuser Plus

Bell & Gossett has a Suction Diffuser Plus product that combines a strainer, elbow, and straightening vane into a single device. Most engineers use this on the base mounted end suction pumps and floor mounted vertical inline pumps. The “Plus” in the name is due to a design that B&G came up with to reduce the pressure drop or Cv of the device. Once again, B&G redesigned the standard in the industry to provide a device with 2% to 5% more efficiency than the competitors.

Bell & Gossett has a Suction Diffuser Plus product that combines a strainer, elbow, and straightening vane into a single device. Most engineers use this on the base mounted end suction pumps and floor mounted vertical inline pumps. The “Plus” in the name is due to a design that B&G came up with to reduce the pressure drop or Cv of the device. Once again, B&G redesigned the standard in the industry to provide a device with 2% to 5% more efficiency than the competitors.

Strainers and suction diffusers both come with an optional startup screen if you specify it. That screen is very fine and simply meant to catch all the debris from the installation. It is so fine that it must be removed a short time after startup.

I’ll write a bit more about the purpose of the suction diffuser next week when the R. L. Deppmann Monday Morning Minutes looks at the pipe connected to the pump suction.