The purpose of the domestic water recirculation system is to deliver hot water near a fixture during times when there is no draw. If someone is using hot water in the next room or apartment or process, the hot water is near enough to your fixture so the hot water is delivered in seconds, not minutes. Today’s R. L. Deppmann Monday Morning Minutes looks at a simple subject, the pressure drop calculations.

The flow of water in a recirculation system is really needed when there is no demand in the system. The flow rate required in the recirculation system was determined in the last article. The pressure drop of the small flow rate, when there is no load, can be calculated similarly to a closed hydronic system. Ignore the elevation and size the return pipe for a reasonable velocity and pressure drop. The hot water supply piping can normally be ignored since the flow rate with no demand will have little supply pipe pressure drop. The exception will be when there are pressure reducing valves, but that will be covered in a later article. The pressure drop will be in the return piping. Determine the pressure drop of the longest run or worst case of pipe and add any equipment pressure drops at the recirculation flow rate.

Determine the Pump Head for a Recirc Pump

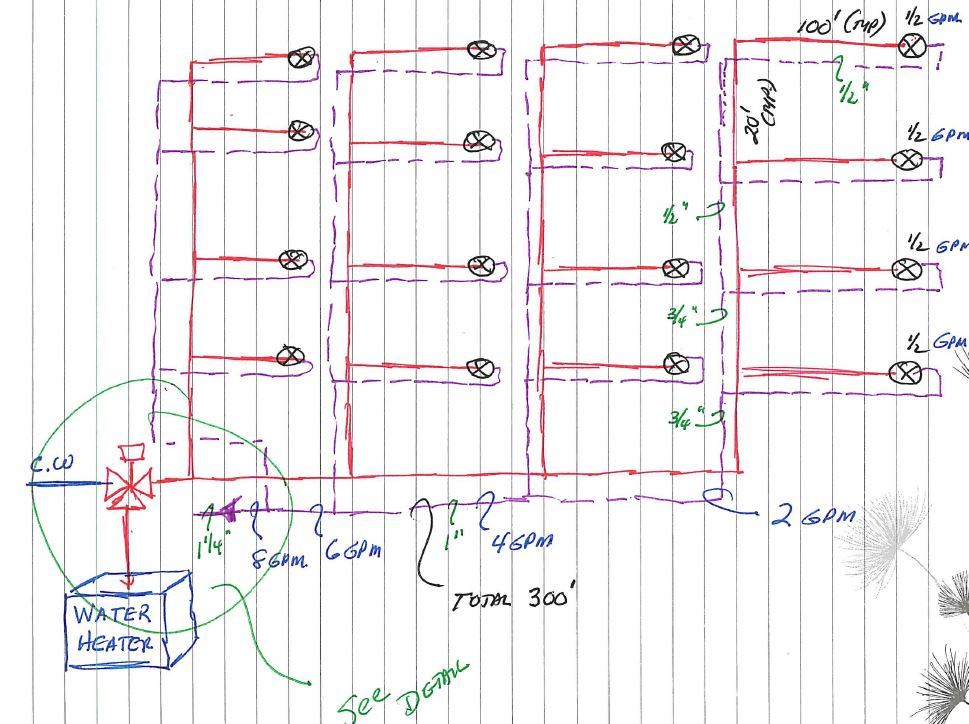

Our example from last week was a 4 story commercial building. It had hot water mains of 4” in the basement and about 300 feet long. There were four 2” hot water risers at 80 feet each and each riser at each floor had about 100 feet of run out using pipe less than 1”. The flow rate was 8 GPM total with 1/2 GPM per return.

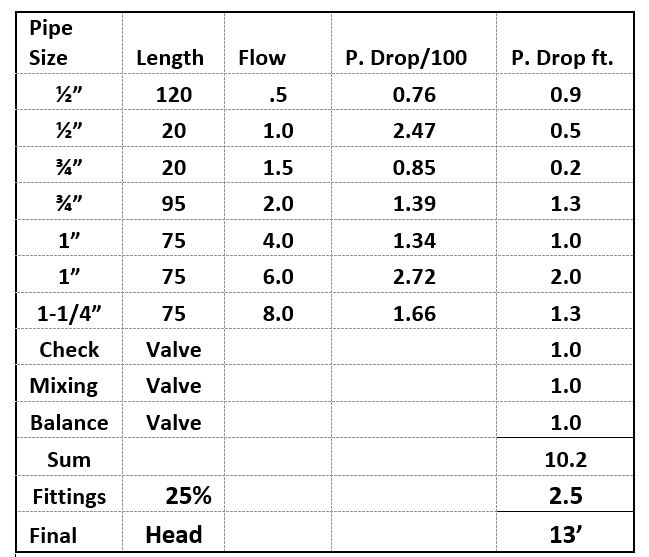

The pressure drop calculations are shown below giving 13 feet. If we would have used the rule of thumb of 4 feet per 100 pressure drop times the 480 feet of pipe, our solution would be over 20’ of head.

Watch for Unusual Diverse Loads

One word of caution on the pump head. Occasionally you will have a design where some of the pressure drop in the supply main would be added to the pump head. If the system has a fairly consistent load near the water heater at times when the rest of the building is not using water, we may add some extra pump head.

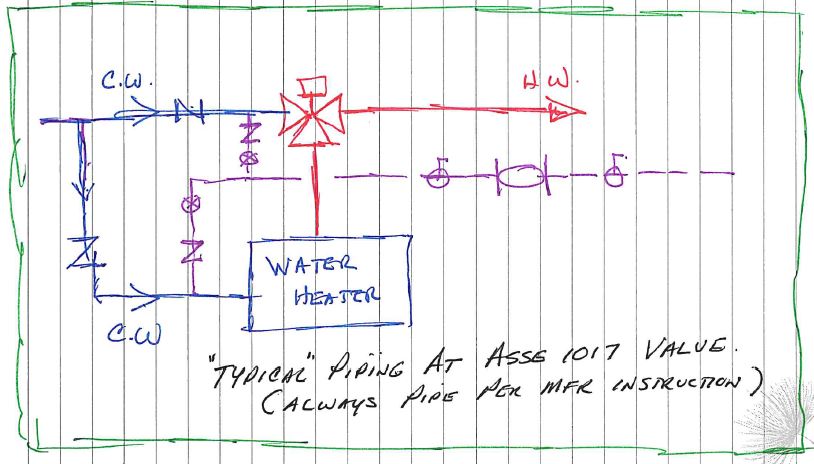

The project I am thinking of was an independent living residence that used a 140°F supply with the point of use mixing valves instead of a master mixer. The 140°F went to a laundry and the kitchen off the same supply as the rooms. In this case, there were 100 feet of pipe at 3 PSIG per 100 that operated early in the morning. The engineer had to increase the recirculating pump head. The issue would go away if there was a separate supply for those load with its own recirc pump. For our example, we will assume this unusual situation does not exist.

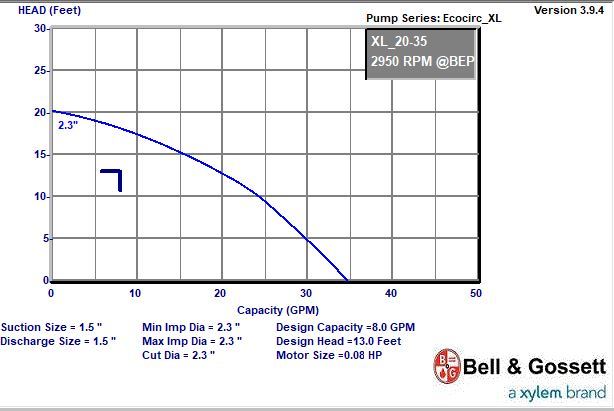

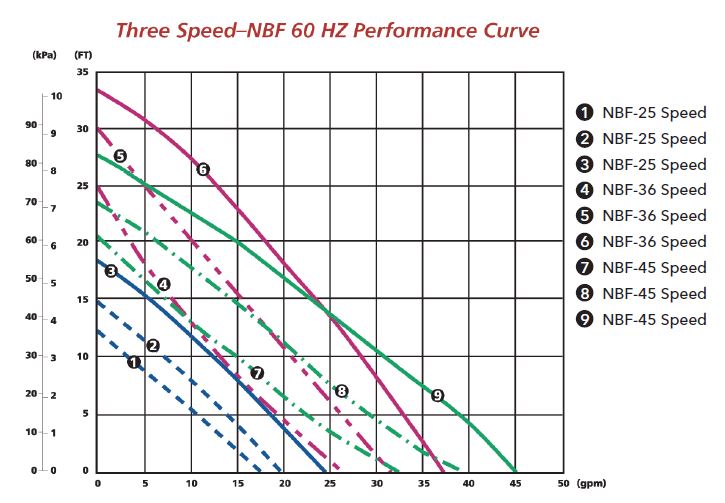

So our pump would be selected for 8 GPM at 13 feet. The Bell and Gossett ESP-PLUS program offers many solutions. As a standard booster pump, we could select a B&G model PL-30B lead-free bronze body pump with 1-1/4” flanges using a 1/12 HP, 115/60/1. We might also select an NBF-25 three speed circulator if we felt the pump head might be oversized.

If the engineer wanted to use a Smart ECM pump, the selection would be the 1/12 HP Ecocirc®-XL N 20-35 with a stainless steel body. This pump will cost about 4 times as much as the standard booster but will eliminate the overheating and reduce the speed when there is usage in the building.

Next week we will look at the control of the circulating pump.

Check out the rest of the Designing Domestic Hot Water Recirculation Systems Series:

- Part 1: Determining the Flow Rate

- Part 2: Determining the Pumping Pressure Drop

- Part 3: Pump Control